secondary clarifier in wastewater treatment

So if there is a serious issue of biomass loss as TSS carryover in the secondary clarifier then the biological process suffers from wash out of useful microbial strains responsible for the. Ad Control fouling in sand filters and clarifiers.

Chemical Oxygen Demand Analysis Of High Cod Sample Dilution Method Science Classes Oxygen Chemical Analysis

- Design and manufacturing of rotating bridges for clarifier tanks of up to d40 m.

. Clarification is a solids separation process which results in the removal of 99 percent or more of the suspended solids biological floc received from the. The steps are as follows. Clarifiers can be installed by modifying the existing facilities.

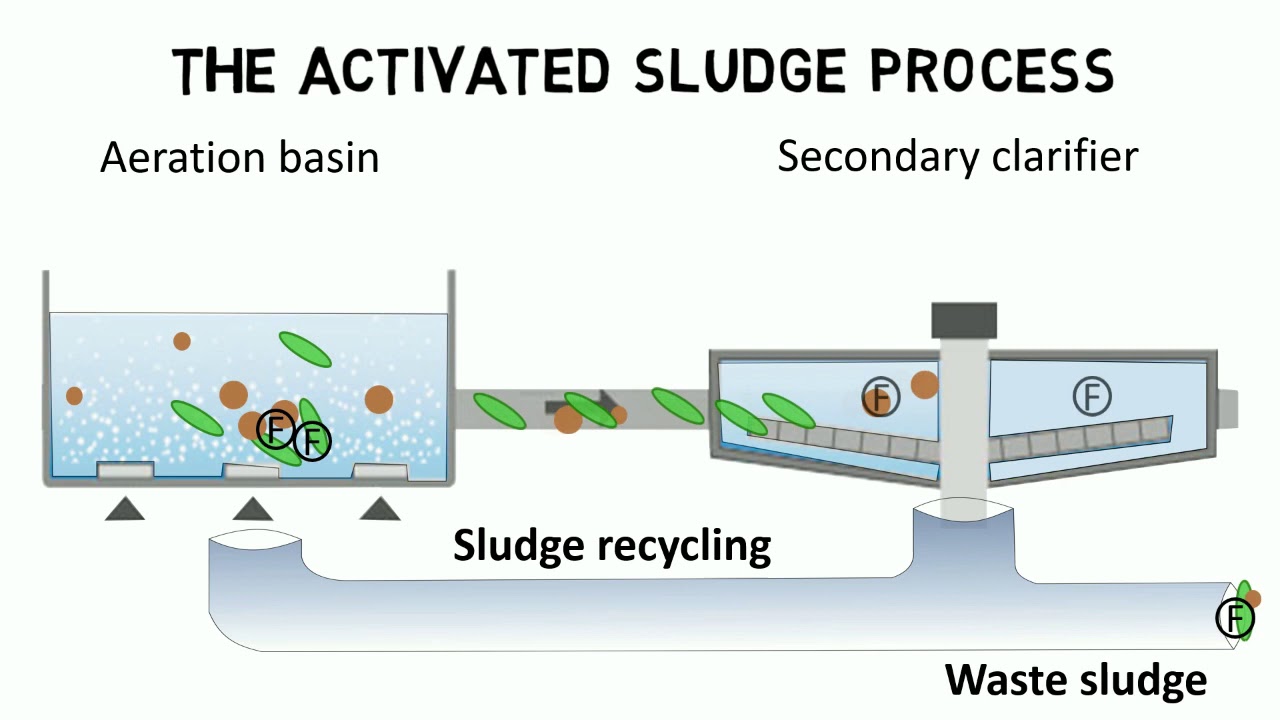

A clarifier is generally used to remove solid particulates or suspended solids from liquid for clarification and or thickening by gravitational settling. Clarifier Secondary Treatment - High reduction of wastewater flow velocity to ensure settling. A circular basin in which effluent from the activated sludge process is held for a period of time during which the heavier biomass microorganisms settle to the bottom as activated sludge.

Secondary clarifiers are aimed at separating the biomass and sending it back to the system in the form of RAS for the further processing of incoming wastewater using this settled biomass. Accepted 18 July 2012. These secondary clarifiers are generally used to remove the bacteria and other microorganisms and removed floc is usually recycled back to the processes where the.

The treated wastewater is then pumped into a secondary clarifier. Mass flow rates of the dispersed phase at the inlet blue peripheral outlet green and central outlet red. Two or more trickling filters may be connected in series and sewage can be recirculated in order to increase treatment efficiencies.

The whole process is known as secondary clarification. Design Circular Peripheral Drive Centre Drive Rectangular Travelling Bridge Chain and Flight. Their primary purpose is to separate the treated wastewater from the natural mass.

Sedimentation tanks or secondary clarifiers remove flocs of biological growth created in some methods of secondary treatment including activated sludge and rotating biological processes. 213 773 22 76 18. These clarifiers are located downstream of biological treatment.

Improve coagulation and flocculation processes. Ad Control fouling in sand filters and clarifiers. D 10 000 to 20 000 gpdft.

- Low maintenance and operational skills required. In primary treatment suspended solids colloidal particles oil and grease are removed. The main purpose of secondary treatment is to remove BOD which does not benefit as much as SS from primary settling.

Received 29 February 2012. Its main goal is to return the activated sludge. 2-After settling over a period of time this biomass of microorganisms is returned to the first aeration tank.

These clarifiers remove microbes that are washed off the rocks by the flow of wastewater. The secondary clarifier is a circular basin that holds effluent from the activated sludge process. In secondary treatment biological treatment is done on the wastewater to remove the organic matter present.

The secondary clarifiers. The secondary sewage treatment is not as efficient in removing the contaminants as the primary treatment of sewage. Prevent clogging of pumps and filters.

Slowly over the floor and surface of the primary clarifier large paddles are rotating that can remove these materials from the wastewater. Getting the right balance of bacteria is key and another good indicator of whether onsite wastewater treatment is working. Entering the two Secondary Clarifiers for wastewater treatment the wastewater is still containing various microorganisms from the basins of aeration and has a murky and brown look.

Secondary clarifiers are used to remove the settlable suspended solids created in biological treatment processes such as the activated sludge and trickling filter process. It is a process which is capable of biodegrading the organic matter into non-polluting end products eg. University of Setif Setif Algeria.

3 SECONDARY TREATMENT Aerobic Process Somore sludgeis produced in aerobic process. Prevent clogging of pumps and filters. Aquatec Maxcon is able to offer various types of Primary and Secondary clarifiers.

213 36 92 84 18. If there are still large particles or solids within the wastewater this is an indication that the primary phase is not operating effectively. Significant amounts of vegetation eg reed grasses.

Secondary treatment aims to remove the remaining organic matter and suspended solids from the wastewater. 1-The biomass of microorganisms settles to the bottom in the form of activated sludge. Clarification is the oldest and most widely used operation in the effective treatment of wastewater.

The secondary or final clarifier is one of the most important unit processes and often determines the capacity of a WWTP. Thus the separation efficiency of the secondary clarifier is 81. These solids are called activated.

Secondary Clarifier To permit any remaining organic sediment to settle out of the treated water flow treated wastewater is pumped into a secondary clarifier. During secondary clarifying microbes germs and smaller particles are removed from the wastewater usually using chemicals and other treatments that make the water safer. These are classified into primary and secondary.

This sludge teaming with hungry microorganisms can be returned to the first aeration basin to begin the activated sludge treatment. Secondary Wastewater treatment is the second stage of wastewater treatment. Trickling filter Settling tanks called secondary clarifiers follow the trickling filters.

Improve coagulation and flocculation processes. The secondary or final clarifier is one of the most important unit processes and often determines the capacity of a WWTP. Characteristics of a Clarifier.

The calculations show that the clarifier removes 052 010 042 kg solid particles per second. Again the aim with the clarifier is for any very small solids to move to the bottom. Secondary treatment of wastewater is a process that follows the primary treatment of sewage.

Hydrology Rainfall Runoff Modeling Ii Synthetic Unit Hydrographs Hydrology Rainfall Linear System

Mbbr Mini Plant For Domestic Wastewater Wastewater Wastewater Treatment Biological Activity

Floating Sludge In Secondary Clarifier Mlss Getting Low Science Classes Science Knowledge Secondary

A Whole New Meaning To Going Going Gone Check Out These Baseball Sewer Stats Infographic Infographic Wastewater Sewer

Types Of Fire Classes Of Fire आग क तन प रक र क ह त ह Science Classes Types Of Fire Knowledge 5th Class

Spray Water At Secondary Clarifier To Scare The Seagulls Wastewater Wastewater Treatment Water

Activated Sludge Process And Ifas Design Rules Guideline Youtube Activated Sludge Design Rules Wastewater Treatment

Hong Kong Water Treatment Plant Infrastructureporn Water Treatment Wastewater Treatment Plant Water Treatment Plant

Pin By Pratikshapokale On Desktop Wastewater Flow Chart Wastewater Treatment Plant

Wastewater Treatment Flow Rates Water Treatment Water Treatment Plant Wastewater Treatment

Water Treatment Wiki Commons Szukaj W Google Wastewater Water Treatment Wastewater Treatment

Electro Oxidaiton에 있는 Industrial Wastewater님의 핀

Separation Phase Fase Pemisahan Pada Proses Fase Pemisahan Terjadi Pengolahan Limbah Cair Menjadi Bentuk Cairan Dan Padata Kualitas Air Air Pengolahan Limbah

Wastewater Treatment 101 Infographic Drenaje Agua

All Things Water Course I Activated Sludge Youtube Activated Sludge Wastewater Treatment Wastewater

Chemical Oxygen Demand Analysis Of High Cod Sample Dilution Method Science Classes Oxygen Chemical Analysis

Biolynk Flush Manure Management Systems Daritech Inc Manure Management System Manure

Separation Phase Fase Pemisahan Pada Proses Fase Pemisahan Terjadi Pengolahan Limbah Cair Menjadi Bentuk Cairan Dan Padata Kualitas Air Air Pengolahan Limbah